What to Look For When Shopping for Siding

Today’s vinyl siding has been re-engineered with advancements that make it durable, sustainable, realistic looking and absolutely gorgeous. If you’re considering siding, here are the advancements to look for when weighing your options.

What gives siding its strength?

Siding is comprised of a series of individual panels that fit together and attach to your home, which create a clean, uniform finish. Many people think the thickness of those panels is what makes them durable, but that isn’t the case: it’s how the panels were designed that counts. In the industry, this is called“engineered geometry.”

Here’s what to look for:

Nail Hems

A nail hem locks one siding panel to another and allows the panel to be nailed into place. The purpose of the nail hem is to provide additional wind load and tear off resistance to each panel. There are a few different types of nail hems available:

- Single nail hem – Found on economy panels and offers only adequate attachment. Comprised of a single layer of material with nail slots, it is the weakest option against nail withdrawal and wind load strength.

- Partially curled nail hem – Found on better panels. Strengthens and reinforces the areas most prone to breaking under negative wind load pressure.

- Full roll over nail hem – Found on premium panels and offers the strongest attachment. The thickness of the entire upper hem is doubled, dispersing pressure all the way around in negative wind load.

Upper and Lower Locks

Upper and lower locks are designed to create stronger interlocks between panels. Locks work in tandem with the nail hems. But first, let’s talk about projection. Projection is simply how far a panel projects from the wall. The taller, or “bigger,” the projection the better because it provides more area to interlock the panels together. A bigger projection also creates more shadow line, which makes it more attractive on the home.

There are a few types of upper and lower locks available:

- Larger channel locks

The biggest and best locks are channel-type locks. These help panels run straighter on the wall, and the locks literally snap in, creating a strong interlock so panels stay tight under high wind pressure. More complexly designed locks offer increased interlocking strength, acting like a beam. The highest-end products are even more sophisticated, dramatically stronger, and keep panels even straighter.

- Bottom lock / return legs – reinforced curls

The bottom lock and return leg is basically the same thing: part of bottom lock of the panel. They increase the strength of the panels, and attachment points, even more. The extra curls act as guides that allow the panels to lock in more easily.

Wind Resistance

When you research siding you’ll find a lot of information about wind resistance. Most siding panels meet VSI Vinyl Siding Product Certification Program guidelines and are rated to withstand various high wind pressures. How much wind pressure your home will be subjected to depends upon variables like the area of the country in which you live, the topography around you and how tall your home is.

Wind creates negative wind pressure as it roars around your house, creating vacuums that can creep behind your siding panels and tear them off. The secret to resisting tear off is to give the panels something to hang on to. The nail hems and upper and lowers locks work together to do just that.

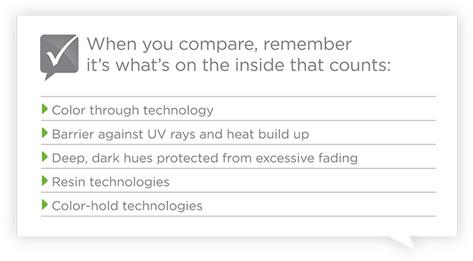

What makes siding durable and fade-resistant?

Re-siding your home is a big investment. The good news is that modern vinyl siding is engineered to outwit the heat, cold, sun and rain. Vinyl siding will also resist fading in the harshest elements.

Here’s what to look for:

- Formulation pigment technologies

Color is more than skin deep. To stay deep and vibrant the color of a panel needs to go all the way through, from top to bottom. If you cut it in half, the color in the cut should be the same as on the surface. The color looks better, resist fading, and scratches don’t show. And, it’s available in an array of deep, rich hues equally protected from fading with proprietary technologies. - Extreme weather performance testing

Beyond making sure a panel’s color runs through from top to bottom, you’ll want to know how it performs in weather extremes. Has the manufacturer you’re considering done their research and testing with the pigments to make sure it will be resilient regardless of the elements? Look for claims or testing to ensure that the pigments that will weather well. Find out where it was tested, too. Testing in the actual desert, in a tropical locale or extreme cold is more realistic than a lab. - VSI Certification

The Vinyl Siding Institute’s color retention certification process requires an outdoor weathering study to be conducted for every color a manufacturer is considering. Each certified color must demonstrate the ability to resist major changes over time in a variety of climates. Currently, over 350 colors have certified color retention.

- Insulated Vinyl Siding

Insulated vinyl siding panels do just what the name implies, providing an insulating effect that reduces heat loss from walls. Some deliver a continuous R3 insulating factor to your exterior. The surface of an insulated panel is bonded to a rigid insulating back, so the panels are wider than usual, giving it a pleasing appearance.

What is the Vinyl Siding Institute?

Some of the biggest innovations in the vinyl siding industry have been brought about by the Vinyl Siding Institute. They help set national building codes and set guidelines that manufacturers must strictly follow in order to achieve certification.